Machines are an inevitable and important part of today’s manufacturing industry. Typical operations in the production process are carried out by working on lathes and CNC lathes. A lathe removes excess material from a rotating tool using a high-powered tool. The primary function of a CNC is to control the machine tool, manage compensation, and improve programming, performance specifications, and evaluation. CNC is used in lathes, drills, mining, machines, milling machines, lasers, machine tools, etc. are widely used. Participants can analyze these processes through the Tool Motion Controller and CNC Simulator and understand the basics of the process.

Virtual Lab helps determine the discharge coefficient of the V-beam, its rectangular orientation, the effect of the beam on the path, the discharge through the venturi meter, and the friction in the pipes. Research objectives include determining the force generated when water flows over a solid surface, using good control methods, measuring speed and force, measuring quality, and improving construction. Participants can easily understand the concept of device emissions by using a standard laboratory and reviewing research using simulations.

Strength of Materials Virtual Laboratory provides information on Young's Modulus, Shear Modulus, Tensile Strength, Deflection, Fatigue Strength, etc. made of hardened steel, aluminum, and welded steel. It helps in determining various mechanical properties of materials such as studying the Mechanical properties of mild steel under heavy load and pressure, ultimate shear strength, double shear, etc. Participants can easily experiment using a standard laboratory.

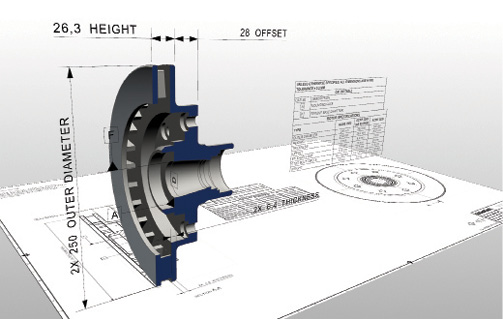

As mentioned technology continues to evolve, and surprising breakthroughs are being made when it comes to the creativity and sophistication of machines specializing in adaptive design, developmental design, and innovative design. Key technologies include computer-aided manufacturing (CAD/CAM), locking and joining, hydraulics, fabrication, construction equipment, and process control. Machine tool design includes the fundamentals of operation, load analysis, material selection, modification, design, and operation. Participants can use the virtual laboratory to familiarize themselves with various design tools/software used in design machine tools () such as AUTOCAD, PRO-E, CREO, CATIA, etc.

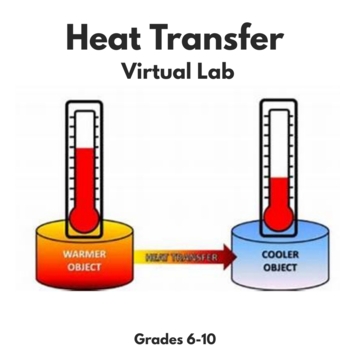

The Heat and Transfer Laboratory provides basic industrial information on heat transfer such as conduction, convection, radiation, and applications. In this laboratory, participants can study and examine phase changes, conduction, and radiative heat transfer, Newton’s laws of cooling, the Seeback effect of thermocouples, black body radiation, and thermistor structure. Various tools are used in the research: Emissivity Measurement Apparatus, Critical Heat Flux Measurement Apparatus, Pin Fin Apparatus, and thermocouple calibration systems

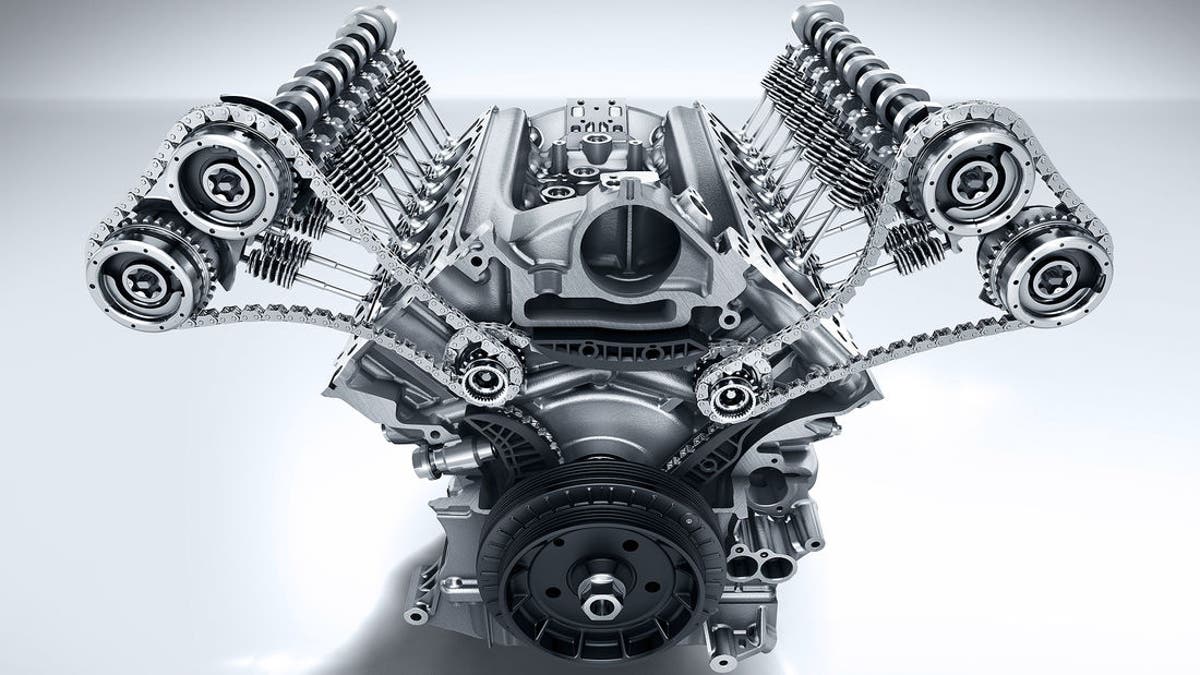

Internal Combustion Engine Virtual Lab aims to understand the basic laws of thermodynamics, heat transfer between systems, heat transfer in the same system, SI and CI engine operation, evaluation of emission parameters, and operation of various engines. Using a typical laboratory, participants will understand the basics of operation of various engines such as 4-stroke multi-cylinder Petrol Engines, 4-stroke 4-cylinder Petrol Engine, 4-stroke 4-cylinder Diesel Engine, 4-stroke single cylinder Duel Fuel Engine, Variable Compression Ratio (VCR) Engine. The setup enables the study of engines for brake power, BMEP, brake thermal efficiency, volumetric efficiency, specific fuel consumption, air-fuel ratio, frictional power, and engine performance parameters like BP, IP, and heat balance sheet.